Business

Daeho-al is preparing for the new future with a competitive advantage in the market.

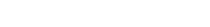

Production Facility

Production Facility

-

2 units of 25-ton melting furnace

Aluminum ingots, scraps generated during the process and equipment used to melt master alloys

-

1 unit of 23-ton retaining furnace

Equipment used to maintain specified alloying constituent and casting temperature

-

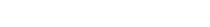

Casting Machine

Equipment used to produce slabs with the use of a direct cooling method

-

Beveler

Equipment used to remove the oxide and ripples on the surface of the slab

-

Homogeneous Furnace

Equipment used to secure the homogeneity of cast structures through beveled slabs heat treated above the recrystallization temperature and to provide heating at a temperature suitable for hot rolling

-

Hot Roller

Equipment used for rolling with a thickness suitable for a cold strip above the recrystallization temperature

-

Cold Rolling Mill

Equipment used to perform the metal forming of hot-rolled coils into the thickness and physical property requested by the client

-

Pressing Machine

Equipment equipped with an auto feeding system pressing into the size of a circle sheet requested by a client

-

Slitter

Equipment used to cut cold-rolled coils lengthways to the client’s desired size

-

Minishare

Equipment used for a width-direction cutting to produce a square sheet (width x length) desired by a client

-

Tension Leveler

Equipment used to correct cold-rolled coils to achieve the image of the sheet flatness requested by the client

-

Annealing Furnace

Heat treatment equipment which secures the physical property requested by the client by reducing work hardening generated during the cold-rolling process